Media fill trials need to be executed on the semi-yearly basis for every aseptic method and additional media fill trials must be performed in case of any adjust in method, procedures or products configuration.

Our line of media fill tests facilitate much easier readings and reinforce the security within your excellent Command procedure.

Determined by the result in the investigation, assign the reason for failure is assignable or not assignable.

one. A single contaminated device really should cause an investigation, including consideration of repeat media fill;

The media fill evaluates the aseptic assembly and operation of vital sterile equipment, qualifies and evaluates the operators' procedure, and demonstrates which the environmental controls are adequate to meet the basic demands for developing a sterile drug via aseptic processing.

Media fills are accustomed to demonstrate the adequacy with the aseptic situations of the pharmaceutical production course of action, In line with very good manufacturing practice (GMP), using a development medium instead of the merchandise solution.

To begin utilizing the Biowelder® TC automated tube welder, an operator inserts the tube holders, the disposable blade and also the TPE tubes and initiates the welding process through the contact display screen.

Sterile, commercially readily available sterilizing filter devices for use on handheld syringes may very well be checked by feeling for better resistance to the plunger when filtering air following an aqueous fluid has long been filtered.

The sealed containers after filling Together with the medium are incubated to detect microbial expansion for contamination at ideal temperature.

If distinct, non-colored containers are usually not obtainable for an APS, Every container have to be aseptically transferred to a clear container for inspection after incubation is accomplished.

Evaluation GP validation, if media was filled immediately immediately after products, and compare them against the particular media filling ailments.

All source items are organized in the DCCA check here so as to reduce clutter and to provide most performance and get with the flow of labor.

How we can easily do to detect the residues of TSB progress medium just after cleaning of equipement? acceptable creteria and by wich want process

Sterile powders, for instance Lactose to be used mediafill validation test in media fills, shall be sterility tested and confirmed for being non-inhibitory by executing progress promotion on a media/sterile powder Option for the focus to be used in Media Fill Test/research.

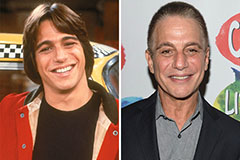

Tony Danza Then & Now!

Tony Danza Then & Now! Alana "Honey Boo Boo" Thompson Then & Now!

Alana "Honey Boo Boo" Thompson Then & Now! Molly Ringwald Then & Now!

Molly Ringwald Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Tiffany Trump Then & Now!

Tiffany Trump Then & Now!